Why Choose Masters Countertops?

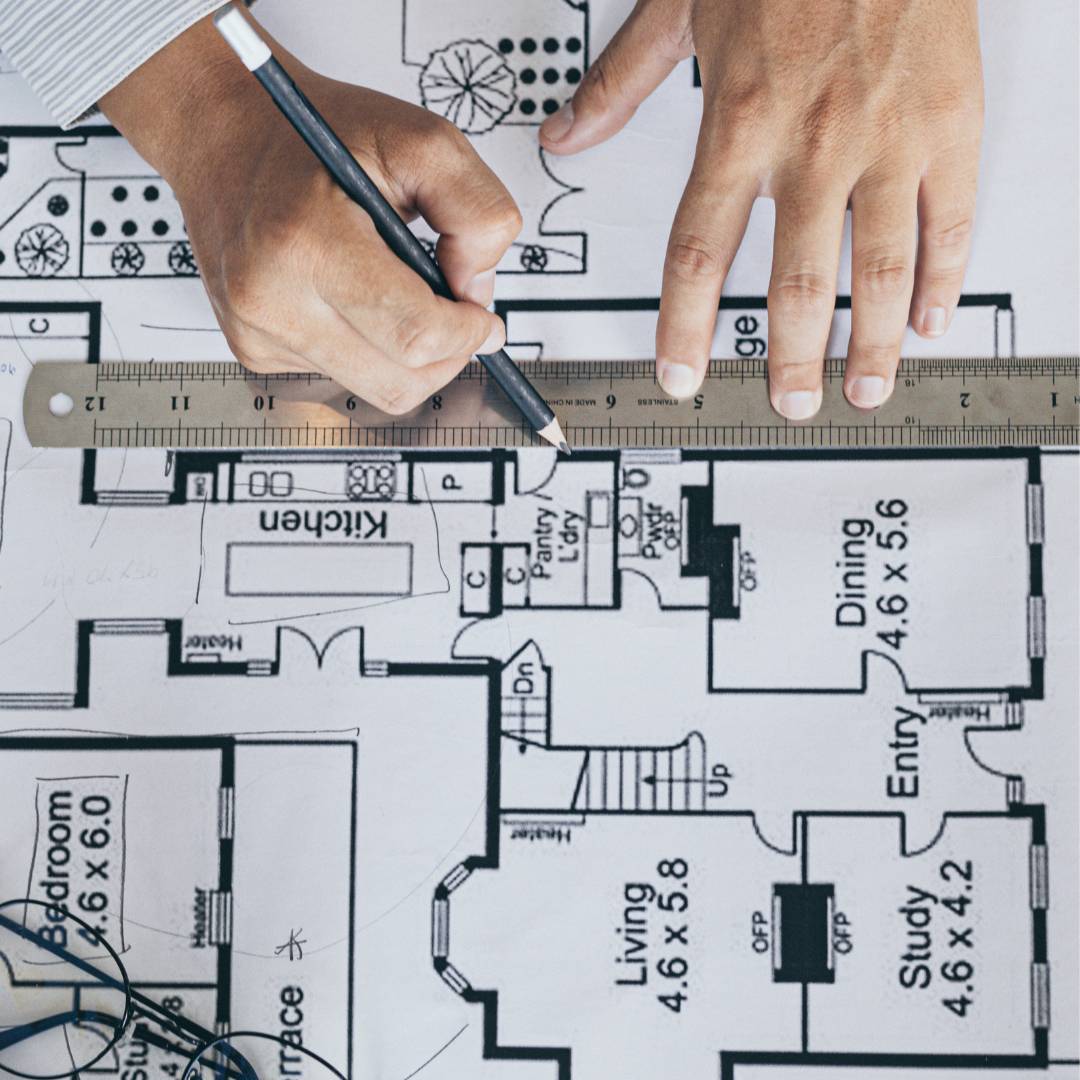

Complete Countertop Layout,

Fabrication & Installation

Masters Countertops is a state of the art manufacturing facility with a beautiful showroom located in Wheeling, IL. We provide a complete Countertop Layout, Fabrication & Installation service.

Precision Scanning for Vein

Matching and 3D Visualization

Each project is measured with a precise 3D laser tool. Selected slab is scanned using the state of the art 14.4K resolution scanner. Scan is used for vein matching and to provide you with a 3D view of what your final project will look like.

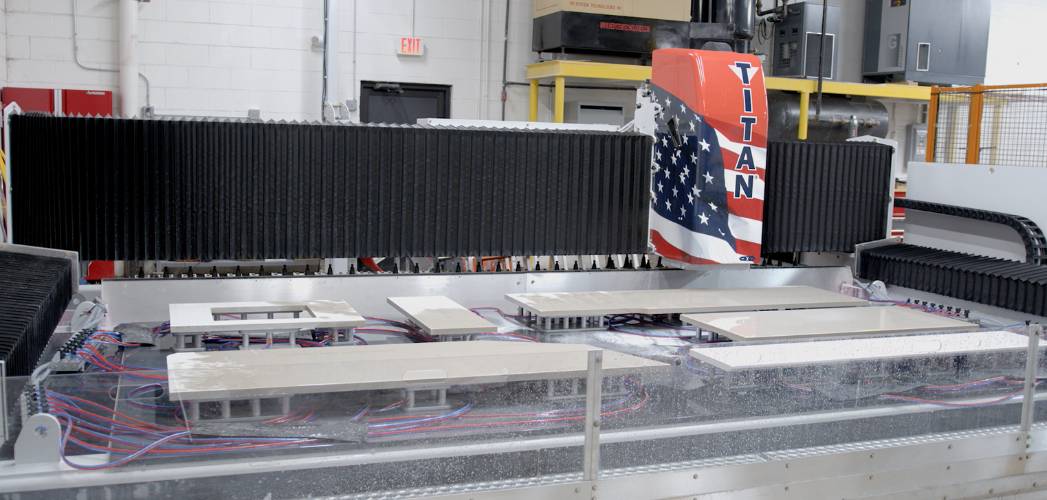

Advanced Robotic Cutting for

Precision and Accuracy

Your countertop is cut using the most advanced robotic saw with integrated water jet in the industry. Automation is key to delivering consistency and quality. It ensures every project is executed with accuracy, resulting in a finish that is consistent, precise, and uniform.

CNC Finishing for

Show-Stopping Countertops

Countertops are finished on a CNC machine to provide you with countertops you will be proud to show off to your friends and family. Our safe, efficient, and eco-friendly fabrication process consistently produces a superior finished product.

Eco-Friendly Fabrication

Our safe, efficient, and eco-friendly fabrication process reduces water usage by 95%. Allowing water to be reused in the shop, making it an ideal solution for both eco-consciousness and operational effectiveness.

Explore Our Showroom:

Hundreds of Samples to Choose From

Our beautifully appointed showroom offers an opportunity to see all of the elements of your project under one roof. We stock over a thousand slabs of Granite, Marble, Quartzite and Quartz as well as samples of hundreds of additional options on display.

Serving Homeowners, Designers, Architects,

Contractors, and Commercial Projects

HUGE CLEARANCE ON STONE COUNTERTOPS

Discover our exclusive stone offers - we've got an outstanding selection at unbeatable prices! With our expert guidance, we'll help you choose the ideal countertop for your space. Don't wait any longer-visit us today and explore our fantastic options!

Testimonials

What customers say about us

Master Countertops are nothing short of amazing. Google needs to have 10 stars for them. Adriana, our manager, was an absolute fab. She understands the whole project patiently and is very honest about the entire process.

The measurement guy and installers do a top-notch job and I love my kitchen now. For all my future projects I will reach out to Master countertops again.

Masters Countertops was professional and responsive from start to finish for our project. They were also competitively priced. The quality of the work was exceptional!

We had a kitchen countertop installed by this company. I can’t say enough good things about them! From Adriana, our sales person, (who followed up on all the details and suggested we go look at the large slab. Thank goodness she did because I almost

picked the wrong one!) to the gentleman that did the measurements (very willing to answer all our questions and explain things and who was very prompt to get the plans back to us) to the installers (who did beyond a great job). The countertop was installed beautifully and not a seam in sight!)

Thank you Masters for the great job. We recommend you highly and we would not hesitate to hire you again!

Tijana was super responsive and knowledgeable. She explained all our options to us

and gave us tips on daily care and install. She helped us through the entire process. Our countertops in both bathrooms are stunning!!! The install crew arrived early (Yes!). They followed all of my HOA rules and directions (and there are a lot of them). They were extremely down to earth, courteous and simply wonderful. Our install crew was Mario, Juan, Ishmael and Adolfo. We will definitely use Master Countertops again. I do recommend them to everyone.

Adriana was very helpful throughout the whole process. We're very happy with our new countertops and if we ever remodel our kitchen again in the future we would happily use Master Countertops again.

From start to finish the whole staff at Masters Countertops was amazing. We met with Adriana and she walked us through the process and followed up after. From Adriana to the gentleman that did the measurements to the guys who installed our countertops everything was great. They answered all of our questions and were very helpful. We will recommend them to everyone in need of new countertops.

Tijana and the team at Masters Countertops were professional, helpful, and fast at getting our fabulous new kitchen counters! We loved working with them and wish we had more counters to redo!

Everyone we dealt with at Masters was great!! Adriana was so helpful in showing us different countertop options that fit what we were looking for, and she was a pleasure to work with throughout the process. The installers carefully removed the old countertops and installed the new ones, with no issues to the backsplash tile or cabinets that we were keeping.

Had such a great experience from start to finish. Tijana helped us find the perfect countertop, and all throughout the process was amazing. The install team was extremely professional and super helpful with explaining everything and how to care for the stone. All in all great experience and hope to do business with them again!

Excellent patient staff, great efficient installation guys, and it looks wonderful. Around half a grand cheaper than other places we looked.

We have now used Masters for two projects in our home. We are so happy with the results. They worked really hard to make sure we understood the process and how the quartz we were using would look and it resulted in a beautiful installation. Would definitely recommend this company.

We couldn’t be happier with our new counters and the service we received from Masters Countertops! From the initial contact and consult with Adriana to the installation crew-everything was top notch! Adriana was amazing—very patient and understanding

with all my questions and very knowledgeable and helpful with the entire process. Cara was wonderful with her communication, scheduling and follow up. The crew was very professional and did a great job with installation and making sure the seams were as

invisible as they could be as well as leaving everything clean. It was stressful going through the initial process of finding the right slabs (going to many different distributors and looking at hundreds of slabs) and then finding the right fabricator but we’re so glad we chose Masters!

We had an excellent experience with Masters Countertops from the start of the process with Adriana as our project manager through selecting the material/design and through installation with Juan. The project manager was very professional, knowledgeable and

understands the process. The showroom is very modern and you can walk around to view the materials. The counters were fabricated within a short period of time. Juan and his crew were great too. They arrived on time in a modern work truck. They had all of

the right tools and were careful when moving the counters. We were very pleased with attention to detail, professionalism and courtesy of the team. I recommend Masters for your project.

This is our second project with Masters and we couldn’t be happier. Adriana is extremely professional and walked us through the process for our countertop and sinks for our new bathroom. The technicians who came to measure were precise and the product was fabricated to perfection. The installation was completed without an incident, professional and perfect, and we are thrilled with our new bathroom. Adriana is a pleasure to work with and kept in contact with us throughout the process, making sure that all our questions or concerns were handled. We highly recommend Masters Countertops for all of your countertop needs. You will not be disappointed.

I’m really impressed with this company! The professional staff especially Adriana who help us through the beginning, middle and end of the process. The men who installed the counter tops were on time, professional and did seamless work. We’re pleased with the outcome of our kitchen counter installation.

Video Gallery

Our Partners

Masters Countertops